Alle Produkte

-

Bruno NascimentoVielen Dank für Ihre kontinuierliche Hilfe und Unterstützung bei der Bereitstellung hochwertiger und erschwinglicher Produkte.

Bruno NascimentoVielen Dank für Ihre kontinuierliche Hilfe und Unterstützung bei der Bereitstellung hochwertiger und erschwinglicher Produkte. -

Ehsan SalmariSchnelle Antwort und professionelle Einstellung machen unsere Zusammenarbeit reibungsloser!

Ehsan SalmariSchnelle Antwort und professionelle Einstellung machen unsere Zusammenarbeit reibungsloser!

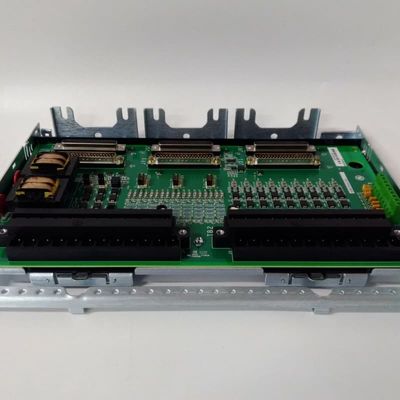

GE IS200TPROS1CBB Processor Module for Mark VI Turbine Control

Produktdetails

| Name | GE IS200TPROS1CBB Processor module | Product ID | IS200TPROS1CBB |

|---|---|---|---|

| Series | Mark VI | Function | Discrete Output pack |

| Product Net Depth/Length | 330mm | Product Net Height | 200mm |

| Product Net Width | 100mm | Product Net Weight | 2kg |

| Warranty | 1year | ||

| Hervorheben | GE Mark VI turbine processor module,IS200TPROS1CBB control module,GE turbine control replacement module |

||

Produkt-Beschreibung

GE IS200TPROS1CBB Processor Module

Product Specifications

| Attribute | Value |

|---|---|

| Name | GE IS200TPROS1CBB Processor module |

| Product ID | IS200TPROS1CBB |

| Series | Mark VI |

| Function | Discrete Output pack |

| Dimensions (L x W x H) | 330mm x 100mm x 200mm |

| Weight | 2kg |

| Warranty | 1 year |

Product Overview

The GE IS200TPROS1CBB is a high-performance Processor Module designed as a core computing component in GE's industrial control systems. This module is typically integrated into Mark series architectures to manage critical turbine and machinery operations with precision and reliability.

Key Features

- Central Processing: Executes control logic and processes real-time data for turbine/machinery regulation, ensuring operational efficiency and safety.

- System Coordination: Facilitates communication with I/O modules, sensors, and HMIs to integrate inputs/outputs and manage system states.

- Reliable Memory: Includes RAM for dynamic processing and flash memory for storing firmware and configuration data.

- Industrial Durability: Built to withstand temperature fluctuations and electrical noise, ensuring stability in demanding industrial environments.

- Diagnostic Capabilities: Features status indicators and self-monitoring tools to aid troubleshooting and maintain system integrity.

- Control System Integration: Seamlessly fits into GE's control architectures, supporting critical functions like fault detection and process optimization.

Product Images

Related Products

Empfohlene Produkte